E-SAT M8 Model 100X100 Cm Desktop Cnc Laser Machine Computer Aided Professional Portable System for 2/3 Dimensional Manufacturing

🧰 You can view the installment options for the products you plan to purchase from the menu below. You can easily purchase all our products with our 12 installment options based on the total amount. Before purchasing, please ask the seller any questions you may have via WhatsApp. We package and send it 💰 Your order is automatically delivered to our production unit immediately after payment and the preparation process begins instantly, according to our business dynamics. 10 max. After all the tests have been carried out, it is sent to you free of charge within 15 days (Immediate Shipments depend on stocks, if the product you purchased is currently in stock, it can be sent within min. 5, max. 7 business days).

WELCOME

PLEASE READ THE PRODUCT DESCRIPTION! ANALYZE OUR MACHINE ACCORDING TO YOUR OWN BUSINESS AND BUSINESS PLANNING.

BE SURE TO ASK THE SELLER VIA MESSAGE FOR ANY DETAILS YOU ARE SQUEERED ABOUT!

PRODUCT MECHANICAL AND ELECTRONIC SPECIFICATIONS

Brand Model: E-SAT M8 100100 Series - 2023 Model ZetCarve

Number of Axes: 3 Axis 4. (AXIS CAN BE SUPPORTED

Control System: Lightburn / LaserGrbl External PC Control Usb

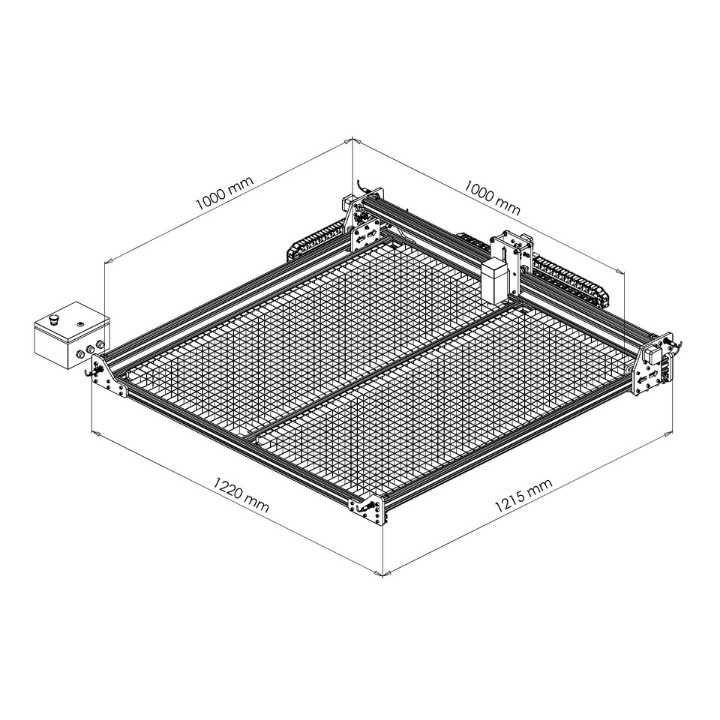

Table Dimensions: 1220X1215 MM

(See Above: Area Measurement Shown in the Technical Drawing)

Working Area: 1000 X 1000 MM

Vacuum Feature: Manual Vise By Hand / Optional

Axis Motors: Micro Precision Stepper Motors on Three Axes

Axis Motor Nm: X-Y-Z 1.6 Nm - 1.6 Nm - 1.6 Nm

Drive System: X - Y Timing Belt/Pulley - Z Hand Held Precision Manual Guideway

Y Axis Slides: TV Sigma 20x40 MM Bearing Combination

X Axis Guides: TV Sigma 20x40 MM Bearing Combination

Z Axis Slides: Z Hand Held Precision Manual Slide

Axial Working Precision: x-y-z +/- 0.001 mm

Machine Sensor Type: Capacitive Proximity Sensor

PACKAGE CONTENTS LIST?

E-SAT M8 CNC LASER 100100 SERIES ALL MACHINE MECHANICS SEMI DISASSEMBLED X1 PIECE

HEX WRENCH (M6-M5-M3-M1.5) X4 PIECES

LASER HEAD MODULE X1 PIECE

(REQUIRED AUXILIARY ELEMENTS X? VARIABLE)

ELECTRONIC CONTROL PANEL X1 PIECE (PC NOT INCLUDED)

DETAILED USER MANUAL X1 PIECE

HOBBLE TABLE IS EXCLUDED

IMPORTANT NOTE! ALL MANUFACTURING DRAWINGS AND FILES OF THE TABLE (TEZG HIN) SHOWN IN THE PHOTOGRAPHS IN THE PRODUCT DESCRIPTION ARE ON OUR STORE PAGE AS A DIGITAL PRODUCT, PROVIDED THAT THEY ARE IN THEIR OWN DIMENSIONS OF EACH MACHINE. YOU CAN LIKE IT! THE PRODUCT IN THIS ADVERTISEMENT IS NOT INCLUDED IN THE PACKAGE!

MACHINABLE MATERIALS AND CUTTING PARAMETERS?

E-SAT M8 Briefly Summarized Definition?

E-SAT M8 is a CNC (Computer Numerically Controlled) 2/3D engraving machine used to cut and engrave wood, plastics and other materials. Here is more information about the basic operation of E-SAT M8;

Who Can Use It and How?

Important Note! Anyone with general computer skills can start using E-SAT M8 in minutes thanks to our comprehensive after-sales installation and usage content! All Videos and Installation Documents and User Instructions are Professionally Included! The Easiest Stages After Sales Are Installation and Usage. Previously Cnc It was manufactured by us so that people and institutions who have never encountered the machine can use it easily. Every user who purchases it can feel comfortable with these details. You can constantly request help from our company wherever necessary!

Simple Usage Steps?

1) Design Creation: The first step is to create the design of your project. You can use Corel/Aspire/Easel programs or various CAD/CAM programs to create this design. The dimensions, shape and details of your design are entirely up to you.

2) Material Preparation: After creating your design, you should fix your carving material to the working area of E-SAT M8 using its vises. This can also be done with methods such as vices-clamps, double-sided strong holding tapes or vacuum tables for some materials.

Materials that can be used with E-SAT M8 include woods, plastics, soft aluminum types and more.

3) Gcode Creation: You will need to create a Gcode file to send your design file to E-SAT M8. Gcode is a standard coding language that gives operating instructions to the machine. Software such as ArtCam or Aspire automatically creates the Gcode suitable for your design.

4, Machining Process: Lightburn/Lasergrbl Cnc interface that controls the spindle and mechanics of E-SAT M8, your design

(reads the converted version into gcode) and gives orders to the machine to process the material. The spindle moves forward-backward or up-down while cutting or carving the surface of the material. E-SAT M8 cuts the material in 2/3 dimensions in accordance with your design or carves.

5, Finishing and Cleaning: When the process is completed, the machine automatically returns to the reference point where it first started, you can repeat this traffic many times as long as requested by the operator, you can now receive the product you designed with E-SAT M8, then the residues of your material are processed by the machine You should clean it from the area, this is a method we insistently recommend that will further extend the life of the machine.

Sharing and Inspiration: When your project is completed, you can share it with other makers and show everyone what you can achieve using E-SAT M8. Additionally, you can get inspired by examining other makers' projects on Social and similar platforms and implement most of the projects you want in minutes. E-SAT M8 100100 series Our cnc Laser machine is a flexible tool for designers of different skill levels and can be used for woodworking, plastic work and more. Thanks to CNC technology, it offers the ability to perform precise and repeatable operations, allowing you to realize many different projects much faster and professionally at an affordable price. It enables your different development projects.

BEFORE AND AFTER SALES INFORMATION

Hello, as pre-sales information about our E-SAT M8 100100 series desktop cnc laser machine, the important details that we can tell you, our valued followers and prospective users, are as follows; our machine is designed and produced with engineering calculations and is primarily suitable for young and old people (8-65 years old). It is produced with precision and high manufacturing experience in order to lead all humanity to digital production, to gain experience in this regard, to develop and realize your finished products easily from idea to prototype, and to produce them at any time, without being dependent on anyone. As our machine segment, you can buy it at the most affordable price in the world market and despite its affordable price, it covers the highest processing areas. Thanks to its desktop compact design, it stands out with its easy installation and use with three different processing area sizes. You can easily send all your questions regarding installation and technical support to your trash can. All required documents and manuals for the programmatic installation and mechanical installation and use of our machine are included in the package. After receiving it from the cargo, you can open your package and start using it in 30 minutes. You can easily contact our live installation support team for any issues you are stuck on and cannot solve. Before making a purchase, please ask the seller your questions via message, for your solution request in your own business planning and in terms of the types of materials you want to process. Please ask your questions via message to analyze whether the workability is possible with our machine. As a result of the purchases you make without analyzing whether our machine will do your job, the machines that have been shipped will not be returned due to the workload placed on us by our industry and intense business dynamics. The manufacturing processes of the purchased machines are started immediately, Since we find your time valuable, we semi-disassemble the machines you have purchased and after carrying out all the electronic - mechanical tests, we move on to the packaging stage. As ZetCarve, we are constantly working to ensure that you can have passive income, start a business, save time, develop your own products, and improve yourself in digital manufacturing. As we work with great faith, we present to you, our valued followers, and to the whole world that we will support your projects and business with great sincerity in your development process in computer-aided production, considering it as our own business,

Regards...

SHIPPING AND PACKAGING INFORMATION

Thanks to our experience in the sector and as a manufacturer company that knows its own products, we package it with the special packaging method we have developed and send it to all countries of the world with ease. We act carefully with a perspective that thinks that cargoes do not take care during domestic and international transportation, and Our company is responsible for all the negativities that may occur in our products related to damage and the problems of not working properly. Since all damaged parts are always in our structure, they are delivered to you as quickly as possible by re-shipping.

WISH YOU HAPPY SHOPPING

İHTİYAROĞLU CNC MACHINE TECHNOLOGIES PRODUCTION AND SUPPLY SERVICES LTD.